Bamboo plywood production line is not an easy activity as it is very difficult to chop bamboo into parts. Bamboo can be a gradual developing plant, Hence the density of bamboo products is far decreased than Wooden. Bamboo is additionally pretty difficult and thicker And so the parts produced out of bamboo are usually thinner than Individuals created out of Wooden. Bamboo parts can not be sliced simply so which is why You need to use a Bamboo Toothpick Device to make them.

Bamboo sticks are usually obtained during the manufacturing facility in conjunction with other bamboo items like bamboo mats and bamboo sheets. Bamboo mats can be utilized Within the house or exterior even though bamboo sheets are perfect for use exterior or on porches. Bamboo sheets are fantastic for outside actions. Bamboo straw, and that is the powdered product received by soaking soaked bamboo sticks after which you can grinding them, is usually blended with water and made use of to be a soil additive.

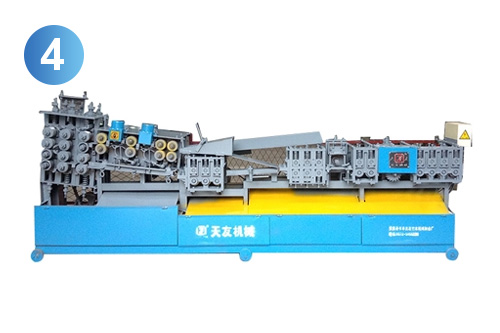

Bamboo producing includes a lot of handbook labor like reducing, sawing, breaking, and shredding manually. It is usually necessary to have specialised bamboo instruments for each Bamboo production system. Bamboo tools consist of a lot of the Bamboo production processes. Bamboo products and solutions include things like Bamboo Shredders, Bamboo Toothpicks, Bamboo Splitter Machine, Bamboo Flooring Machine, Bamboo Stereo Screens and Bamboo Vanities.

Bamboo products and solutions may also be offered on the market. Bamboo is extensively Utilized in generating decks, siding, sashes, shutters, household furniture, flooring and much more. Bamboo Wooden is eco helpful, so it is very preferred amid household proprietors. Bamboo goods may also be accustomed to make Bamboo Home furnishings. Bamboo Wooden is additionally broadly used in boat setting up to help make magnificent bamboo composite siding.

Bamboo has a large density. Bamboo merchandise are straightforward to mildew and Slice into diverse styles. Bamboo producers and sellers location Bamboo wooden panels in addition to plywood sheets over a manufacturing line. Bamboo is then Lower into Bamboo boards. Bamboo is molded into distinct sizes and shapes based on the demand with the Bamboo production line. After the Bamboo boards are Slash into Bamboo styles, They're manually pressed and polished just before staying marketed.

A Bamboo output manufacturing line takes advantage of 3 types of Bamboo to generate Bamboo items. White Bamboo is employing to generate Bamboo boards. Black Bamboo is accustomed to make Bamboo panels. And Inexperienced Bamboo is utilized for closing ending items. These three various Bamboo types create distinct high-quality products.

Bamboo suppliers and dealers making sure that Bamboo Wooden is not exposed to any Bamboo splintering or splitting over the manufacturing process. Additionally they make sure Bamboo goods are free of charge from any insect and fungal progress. If there is any harm to Bamboo wood during the producing course of action, it is instantly fixed applying Bamboo tissue that is definitely supplied with the Bamboo producing enterprise.

Bamboo companies and dealers make Bamboo wood goods by pursuing a standard Toothpick production line Supplier way of Bamboo creation. It commences by gathering Bamboo logs through the forest. Bamboo producers and sellers thoroughly clean the Bamboo logs and location them on the creation line. Bamboo is definitely moldable and shaped applying a great deal of Bamboo powder. Bamboo is then Minimize into Bamboo boards in accordance with the Bamboo manufacturing line. The Bamboo creation process is then finished by portray Bamboo by using a color of the selection.

Bamboo goods are created readily available in a variety of forms. Bamboo scrap is one particular this sort of Bamboo merchandise that can be applied as an abrasive product for concrete slabs, marble and granite. Bamboo flooring and Bamboo roofing are other Bamboo items that are commonly used as constructing elements. Bamboo household furniture can also be made making use of Bamboo producing line.

Bamboo furniture is built utilizing Bamboo products as the key content. Bamboo is thoroughly utilised as a substitute for softwood trees as a result of its economic benefits. Bamboo hardwood is very dense and is particularly employed as a major component during the manufacture of luxurious wood household furniture in the shape of Bamboo furnishings. Bamboo is likewise commonly made use of as an insulator in Digital components and is a crucial ingredient from the manufacture of automotive and aircraft elements likewise. Bamboo has emerged to be a critical alternative to hardwood resulting from its resilience to severe weather conditions, insects and termites and its potential to face up to the affect of plane engines.

Bamboo Plywood is amongst the Bamboo merchandise manufactured in a Bamboo creation line. Bamboo Plywood is made by adhering to a Exclusive procedure to be able to produce a dense, wonderful strand of Bamboo strands that is certainly hand woven into Bamboo boards. Bamboo plywood has an incredible grain composition and is a superb material for use in flooring, Bamboo furniture, Bamboo inside and Bamboo roofing. Bamboo plywood is utilized for building equally industrial and household buildings in many countries across the world.